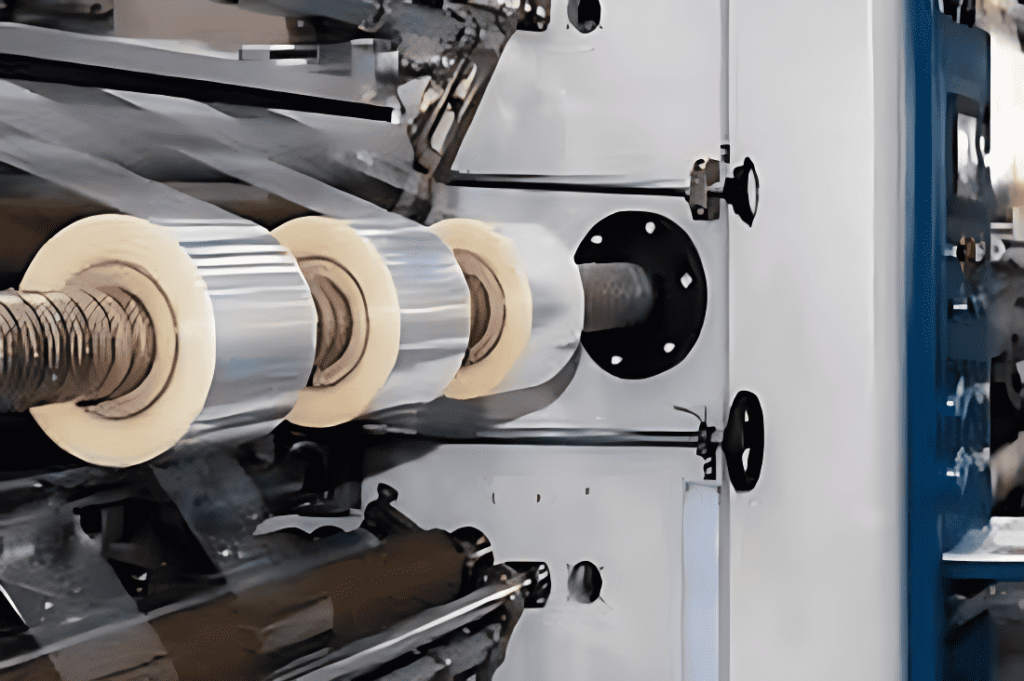

Slitting and Sheeting Thin Gauge Film: Efficiency and accuracy are essential in today’s production environment, particularly when handling thin gauge films. Converting equipment for slitting and sheeting is essential for sectors that demand precise measurements, unique sizes, and superior finishes. The proper converting equipment guarantees that thin gauge films are processed with the least amount of waste and the highest uniformity, whether they are used for electronics, medical packaging, or automotive applications.

Recognizing the Value of Sheeting and Slitting Film with a thin gauge

Because of their adaptability, low weight, and simplicity of handling, thin gauge films are extensively employed in many different industries. Usually less than 0.5 mm thick, these films can be manufactured from a variety of materials, including PET (polyethylene terephthalate), polyethylene, polypropylene, and specially designed plastics.

Working with such tiny materials, however, may be difficult; accuracy is essential because even the tiniest discrepancies can result in waste, manufacturing delays, or defective products.

This problem can be resolved by converting slitting and sheeting machinery. Businesses may maintain excellent product quality and customer satisfaction by using sophisticated gear and procedures to make thin gauge film goods that fulfill precise standards.

How Efficiency Is Increased by Slitting and Sheeting Equipment

Precision Cutting: Thin gauge films are cut into the precise widths or sizes needed for downstream applications thanks to the slitting and sheeting operations’ ability to produce incredibly accurate cuts. Whether you need rolls, sheets, or custom shapes, the equipment allows for precision cutting that minimizes material waste.

Better Material Handling: Because thin films are brittle, they are more likely to rip or stretch. Converting equipment helps ensure the material is handled with care, preventing damage during the slitting or sheeting process. Additionally, automated systems help reduce manual intervention, further minimizing the risk of errors.

Customization for Particular Uses: Because converting equipment is so adaptable, businesses can make narrow gauge films to meet the needs of particular clients. The ability to modify the cutting parameters guarantees that every film result is suitable for its intended use, whether it is for packaging, electronics, or medical equipment.

Increased Throughput with Reliability: Converting machinery is made to process large amounts of material with constant quality. Without compromising accuracy or economy, this scalability guarantees that producers can satisfy demand whether creating small batches or large-scale runs.

Important Characteristics of High-Performance Sheeting and Slitting Equipment

Investing in high-quality, cutting-edge converting equipment is crucial to achieving these advantages. Important characteristics to search for are:

Adjustable Slitting Heads: Manufacturers may easily alter the cutting widths with adjustable slitting heads, allowing them to produce a range of product sizes from a single thin gauge film roll.

Inline Inspection and Quality Control: To keep an eye on the quality of the film in real time, many contemporary converting machines have built-in inspection systems. This reduces waste and the need for reworks by guaranteeing that flaws like creases, bubbles, or misalignments are detected right away.

Winding and Unwinding Stations: The best converting equipment has strong winding and unwinding mechanisms that keep the film from tangling or wrinkled during processing, ensuring a seamless production.

Effective Management of Waste: Although precision slitting produces very little waste, the best equipment also has systems for effectively handling trash, which lowers production costs and the environmental impact overall.

Utilizing Converting Equipment for Thin Gauge Film Slitting and Sheeting

Slitting and sheeting thin gauge film has a wide range of uses. This technology is essential in a number of important domains, including:

Packaging: Flexible packaging, where high transparency and barrier qualities are crucial, frequently uses thin gauge films. Slitting and sheeting equipment guarantees that film is exactly proportioned to satisfy the needs of packaging machinery, whether it is for consumer items, food, or pharmaceuticals.

Medical Devices: Thin gauge films are necessary for a variety of medical applications, including sterile packaging and wound care products. In order to maintain hygienic standards and regulatory compliance, converting equipment helps guarantee that the film is cut to exact proportions for usage in medical devices or packaging.

Electronics: Flexible circuits, displays, and insulation are just a few of the electronics applications that use thin films. These films are trimmed to the proper thickness and dimension for a smooth integration into electronic devices thanks to slitting and sheeting equipment.

Automotive: Thin gauge films are frequently utilized in parts such as weather-resistant films, soundproofing, and protective coatings in the automotive sector. These films are guaranteed to satisfy the exacting performance requirements needed for automotive applications thanks to precision cutting.

Why Pick Cutting-Edge Converting Equipment for Your Needs in Thin Gauge Film?

Purchasing cutting-edge conversion machinery to slice and sheet thin gauge film has a number of clear benefits.

Decreased Operational Costs: Modern machinery helps minimize production costs without sacrificing quality by increasing throughput, decreasing waste, and enhancing cutting precision.

Faster Time-to-Market: Product delivery is guaranteed by effective film processing, which helps companies satisfy customer demand and remain competitive.

Superior Quality: Consistent and accurate cuts are made by high-performance slitting and sheeting equipment, guaranteeing that final goods satisfy the strictest requirements for dependability and quality.

In Conclusion

Converting equipment for slitting and sheeting thin gauge film is essential in industries where accuracy is crucial for ensuring that materials are processed effectively, with the least amount of waste and the highest quality possible. With cutting-edge machinery, producers can maximize operational efficiency while satisfying the needs of a wide range of applications, including electronics, medical devices, and packaging.

Businesses may maintain their competitiveness, increase their profitability, and produce goods that surpass customer expectations by investing in high-quality conversion equipment.

Your company can fully realize the promise of thin gauge film processing and establish itself as a leader in efficiency and quality by utilizing the most recent advancements in converting technology.